I recently had the opportunity to chat to a large, successful manufacturing company about their CSRD requirements. While I expected this to be a straightforward “we know we have to do this, so where do we start?” conversation given their size, I was instead afforded valuable insights into the pain points manufacturing companies face on a day-to-day basis in relation to their sustainability.

Although this particular company had a seemingly healthy turnover, it quickly became apparent that their long-term security and viability was heavily dependent on their ability to win and retain customer contracts on an on-going basis. While this was easier in the past, due to the high quality of their work and calibre of personnel, over the last few years they have been presented with more and more ‘non-functional’ requirements in the area of sustainability. This is due to the multi-national nature of their key customers, upon whom they rely for survival.

These non-functional requirements were required by their primary stakeholders as they themselves were in scope for sustainability and corporate legislation pre-dating the Corporate Sustainability Reporting Directive (CSRD), such as the EU’s Non-Functional Reporting Directive (NFRD), the UK’s Modern Slavery Act and Corporate Governance Code, South Africa’s King Code of Governance, California’s Climate Corporate Data Accountability Act and the French Grenelle policies.

While this was manageable for the leadership team initially, with the onset of CSRD they have seen a significant rise in requests for information or certification through a myriad of different platforms and initiatives such as the CDP questionnaires, the Science-Based Targets initiative, EcoVadis, B-Corp and a wider range of ESG data-scraping companies who take on the leg work of supply chain validation for a small per-company fee. Note: This outsourcing of supply chain validation is quite an attractive proposition to many companies due to the hundreds and thousands of suppliers they may have, so the number of these ESG data mining companies that exist are on the rise.

The issue for suppliers in these customer supply chains, as has been seen by this particular manufacturing company, is that each customer may opt to use a different company for data collation which results in multiple different requests for information, varied required response formats and multiple deadlines for different requests. This is incredibly time consuming and to date, due to the tight RFP windows they must adhere to, has been done by this particular management team in a reactive, fire-fighting fashion for each bid or tender.

Realising that this approach is not sustainable in the long-term, the manufacturing company’s leadership team have come to the conclusion that they must try to get ahead of these multiple requests for information by producing their own detailed sustainability report. Once produced, this could then be accessed or referred to by whomever needs or wants this information going forward. For this particular company this realisation coincided with their legal requirement to produce a CSRD report, but for smaller manufacturing companies not in scope for the legislation, the same logic applies.

If you are a manufacturing company or a company in another sector which is similarly dependent on winning and retaining tenders, getting to grips with your sustainability is something you simply cannot afford to ignore any longer. Ideally you would hire someone to take on this role for your company as you would be amazed at what the right person in this role could achieve. Alternatively, you could outsource but in doing so, risk losing a valuable opportunity to up-skill your staff. Sustainability is not a once-off project, it is an ongoing endeavour of impact management. Therefore a completely hands-off outsourcing approach will cost you more over time and increase your risk. The third approach is a hybrid of the two. It involves up-skilling your existing staff through training and supportive tools and by engaging consultants who are intent on empowering your teams to deliver for themselves going forward.

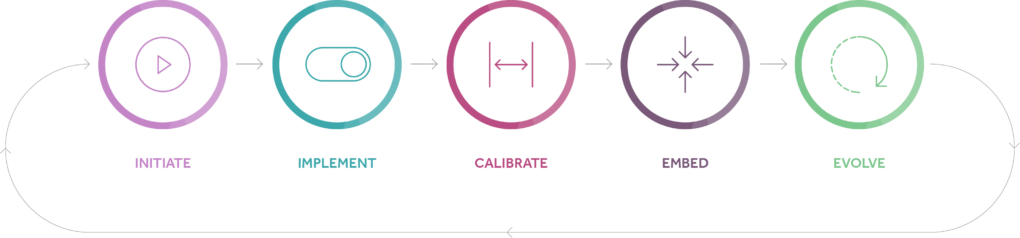

This is our mission in RBESG. We want to empower companies to become and remain sustainable. Our product STS Plan for example is a self-guide solution which walks companies step-by-step through the sustainability transformation process, enabling them to do this themselves, at their own pace, in line with available budgets. STS Implement is a management information system designed to let companies track and manage their sustainability data in-house without the need for ongoing subscriptions or costs. STS Report is a set of reporting templates to enable companies report in accordance with international sustainability reporting standards and frameworks.

For those that prefer a more guided approach, our consultants help teams get to grip with key concepts such as sustainability governance, due diligence, strategy and reporting and can help companies identify their material impacts, risks and opportunity. We can also help with sustainability specifics such as Greenhouse Gas Accounting for Scope 1, 2 and 3 emissions.

If you’re ready to take the first step on your sustainability journey, we would love to hear from you. You can schedule a complimentary 1:1 with us through the booking form on our website, call us on +353 1 516 1064 or email us on info@rbesg.com. There is absolutely no obligation to buy, we love to chat and connect and if we can help you with some simple advice on the phone we’re happy to do so. What have you got to lose? Carpe diem!